Spin separators to protect your plants

avoid condensate rainouts

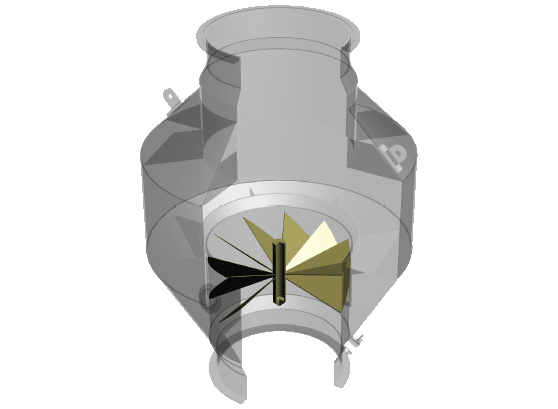

Spin separators are used in ventilation, air conditioning and process engineering to prevent condensate precipitation from exhaust air systems with flues, piping, gas scrubbers and so on. The installed setup is suitable for both vertical and horizontal flow.

The gas/liquid mixture is made to rotate inside the separator. The centrifugal forces generated cause the entrained liquid drops and solids on the inner wall of the separator to flow outwards via a condensate drain.

Separation depends mainly on the medium’s geometry, throughput and concentration.

Spin separators

DAH/V

Application

- ideal for separating droplets and solids

- primarily used to prevent precipitation from flues, pipelines and gas

Features

- flow rate from 1500 to 32000 m³/h

- available in 6 nominal diameters from 315 to 1000 mm

| Volume flow | 1.500 to 32.000 m³/h |

|---|---|

| Nominal diameters | 6 nominal diameters from 315 to 1000 mm |

| Material | PP, PPs, PE, PDVDF, GFK |

| Atex | optionally suitable for installation in and extraction from ATEX zone 2 or ATEX zone 1 in electrically conductive version |

| Connection options | suitable for both vertical and horizontal flow |