Customised fans

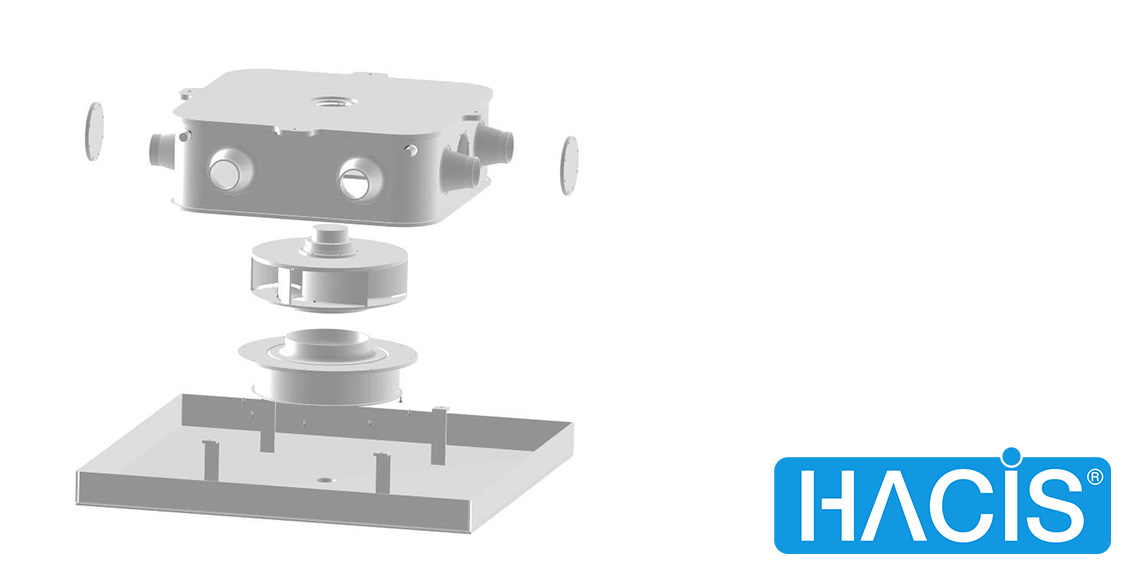

HACIS® ductless ventilation system – food safe

Contaminated atmospheric conditions in food production not only influence the quality of the food, but also lead to high bacterial loads in the air. The consequences are spoiled goods and faulty production, generating considerable costs.

The specially developed ductless HACIS ventilation system is equipped with UV-C disinfection technology. Its use results in a steady reduction in bacteria and prevents microbiological growth in the form of bacteria, mould or yeasts.

Developed in cooperation with:

PGH Ingenieurgesellschaft für technische Gebäudeausrüstung mbH

Eremitagestraße 36

95448 Bayreuth

Deutschland

Tel: + 49 921 5 07 20 67 – 0

Fax: + 49 921 5 07 20 67 – 99

E-Mail: info@pgh.de

www.pgh.de

Customised fan

HACIS®

- can be used in all food industry applications (food safe)

- for optimal atmospheric conditions or regulated ripening conditions in dairies

- meets all the food industry’s hygiene requirements

- ptionally suitable for installation in and extraction from ATEX zones 2 and 1

- volume flow from 500 to 2500 m³/h

- at a maximum pressure difference of 550 Pa

- available in the nominal diameter of 280 mm

| Volume flow | 500 to 2.500 m³/h |

|---|---|

| Pressure difference | 550 Pa |

| Efficiency level | up to 83 % |

| Nominal diameters | 1 nominal diameter of 280 mm |

| Operating temperature | 0 – 60 °C |

| Impeller material | natural PP |

| Drive system | direct drive |

| Atex | optionally suitable for installation in and extraction from ATEX zone 2 or ATEX zone 1 in electrically conductive version |

| Connection options | no supply and exhaust air ducts required |

Advantages:

- use of food-safe natural PP

- up to 40% lower investment costs

- up to 60% lower operating costs

- special design prevents emission of hazardous radiation

- integrated UV-lamp with shatter protection

The following accessories are recommended for this product:

C&I technology

C&I technology

ATEX

ATEX