Centrifugal fans

plastic centrifugal fans for conveying chemically aggressive exhaust air

HLU’s plastic centrifugal fans are specially designed for conveying chemically aggressive exhaust air. Their distinguishing feature is their extreme resistance to corrosion. They also generate high volume flows and pressure differences with optimum efficiency. Centrifugal fans are the efficient “all-rounders” of plastic fans. HLU offers you the perfect solutions for your needs, from standard products to individual bespoke products. For use in potentially explosive areas, all series are available in an explosion-proof version for zones 2 and 1 in accordance with ATEX.

Small centrifugal fans

HF R 75/110

- can be used in all applications with small air volumes

- low weight and compact dimensions ensure easy installation

- ideal for 24-hour exhaust air extraction from chemical storage cabinets

- optionally suitable for installation in and extraction from ATEX zones 2 and 1 Features

- volume flow from 15 to 500 m³/h

- at a maximum pressure difference of 420 Pa

- available in nominal diameters 75 mm and 110 mm

| Volume flow | 15 – 500 m³/h |

|---|---|

| Pressure difference | 420 Pa |

| Nominal diameters | 75 and 110 mm |

| Operating temperature | 0 – 60 °C |

| Housing material | PPs-el |

| Impeller material | PPs-el |

| Drive system | three-phase or AC motor |

| Atex | suitable for installation in and extraction from ATEX zone 2 as standard, optionally for ATEX zone 1 in electrically conductive version |

| Design | with shaft seal as standard |

| Connection options | pipe or flange connection |

Advantages:

- corrosion resistant

- compact design

- versions for different installation situations

- fast availability of the standard variants

- motor mounted outside the airflow

- use of different motors (explosion-proof motors) possible

The following accessories are recommended for this product:

Centrifugal fans

HF R 15/17

- can be used in all applications with medium air volumes

- ideal for extraction from fume hoods and chemical storage cabinets in laboratories

- also suitable, with optional accessories, for more demanding industrial applications, such as tank vapour extraction in the electroplating industry

- optionally suitable for installation in and extraction from ATEX zones 2 and 1

- volume flow from 100 to 15000 m³/h

- at a maximum pressure difference of 5000 Pa

- available in 12 nominal diameters from 125 to 500 mm intake diameter

| Volume flow | 100 – 15.000 m³/h |

|---|---|

| Pressure difference | 5.000 Pa |

| Efficiency level | up to 81% |

| Nominal diameters | 12 nominal diameters from 125 to 500 mm |

| Operating temperature | 0 – 60 °C |

| Housing material | UV-beständiges PEs |

| Impeller material | PPs, GFK, CFK |

| Drive system | direct or belt drive |

| Atex | optionally suitable for installation in and extraction from ATEX zone 2 or ATEX zone 1 in electrically conductive version |

| Connection options | pipe or flange connection |

Advantages:

- corrosion resistant

- energy efficient

- weatherproof

- compact design

- graduated sizes

- fast availability of the standard variants

- suction and discharge openings with the same diameter

- comprehensive range of accessories

- motor mounted outside the airflow

- use of different motors (explosion-proof motors) possible

The following accessories are recommended for this product:

Centrifugal fans with EC motors

HF R 15/17 EC

- ideal for energy-sensitive applications and modernisation measures

- optionally suitable for installation in and extraction from ATEX zone 2

- volume flow from 100 to 3000 m³/h

- at a maximum pressure difference of 1600 Pa

- available in 6 nominal diameters from 125 to 250 mm

- very simple speed control with EC motor with integrated control electronics

- optional control via external 0 to 10 volt signal or Modbus interface

| Volume flow | 100 – 3.000 m³/h |

|---|---|

| Pressure difference | 1.600 Pa |

| Efficiency level | up to 81% |

| Nominal diameters | 6 nominal diameters from 125 to 250 mm |

| Operating temperature | 0 – 60 °C |

| Housing material | UV-beständiges PEs |

| Impeller material | PPs |

| Drive system | energy-efficient EC motor |

| Atex | optionally suitable for installation in and extraction from ATEX zone 2 |

| Design | speed controller and repair switch ready wired |

| Connection options | pipe or flange connection |

Advantages:

- safe and easy to use and install

- easy connection (plug & play)

- high efficiency level

- low power consumption

- optimally integrated monitoring function

- infinitely variable speed

- compact design

- no additional parts necessary

The following accessories are recommended for this product:

Centrifugal fans

HF R 13/16

- can be used in all applications with large air volumes, such as electroplating tanks, the semiconductor industry, water treatment plants and special applications involving process exhaust air

- ideal for extraction of collected exhaust air from large laboratories at universities, research institutes and in the chemical industry

- the wide range of possible materials for the housings and impellers means that they can be optimally configured to meet specific requirements

- optionally suitable for installation in and extraction from ATEX zones 2 and 1

- volume flow from 3000 to 250000 m³/h

- at a maximum pressure difference of > 5000 Pa

- available in 18 nominal diameters from 160 to 1600 mm intake diameter

| Volume flow | 3.000 to 250.000 m³/h |

|---|---|

| Pressure difference | >5.000 Pa |

| Efficiency level | up to 81% |

| Nominal diameters | 18 nominal diameters from 160 to 1600 mm |

| Operating temperature | 0 to 70 °C |

| Housing material | PPs |

| Impeller material | PPs, FRP, CFRP, steel coated |

| Drive system | direct, belt or clutch drive |

| Atex | optionally suitable for extraction from ATEX zone 2 or ATEX zone 1 in electrically conductive version |

| Design | frame galvanised as standard |

| Connection options | pipe or flange connection |

Advantages:

- corrosion resistant

- high efficiency level

- motor mounted outside the airflow

- use of different motors (explosion-proof motors) possible

The following accessories are recommended for this product:

High-pressure fan

HF R 48

- for achieving high pressures at low flow rates

- ideal for applications with relieving hoods, multi-stage exhaust air purification, liquid baths and many special applications involving process exhaust air

- the wide range of possible materials for the housings and impellers means that they can be optimally configured to meet specific requirements

- optionally suitable for installation in and extraction from ATEX zones 2 and 1

- volume flow from 100 to 7000 m³/h

- at a maximum pressure difference of > 7000 Pa

- available in 7 nominal diameters from 50 to 200 mm intake diameter

| Volume flow | 100 to 7.000 m³/h |

|---|---|

| Pressure difference | 7.000 Pa |

| Efficiency level | up to 60% |

| Nominal diameters | 7 nominal diameters from 50 to 200 mm |

| Operating temperature | 0 – 70 °C |

| Housing material | PPs |

| Impeller material | steel coated |

| Drive system | belt drive |

| Atex | optionally suitable for extraction from ATEX zone 2 or ATEX zone 1 in electrically conductive version |

Advantages:

- corrosion resistant

- high-pressure version up 7000 Pa

- no metal parts in the airflow

- motor mounted outside the airflow

- use of different motors (explosion-proof motors) possible

The following accessories are recommended for this product:

High-pressure fan

RV 20

- can be used in all applications with medium air volumes

- ideal for extraction with high pressure differences

- also suitable, with optional accessories, for more demanding industrial applications, such as tank vapour extraction in the electroplating industry

- optionally suitable for installation in and extraction from ATEX zones 2 and 1

- volume flow from 80 to 2500 m³/h at a maximum pressure difference of >6500 Pa

- available in 4 nominal diameters from 80 to 140 mm intake diameter

| Volume flow | 80 to 2.500 m³/h |

|---|---|

| Pressure difference | 6.500 Pa |

| Efficiency level | up to 76% |

| Nominal diameters | 4 nominal diameters from 80 to 140 mm |

| Operating temperature | 0 – 60 °C |

| Housing material | PP, PPs, PVC, PE, PVDF |

| Impeller material | PP, PPs, PVC, PVDF, FRP, CFRP, steel coated |

| Drive system | direct or belt drive |

| Atex | optionally suitable for installation in and extraction from ATEX zone 2 or ATEX zone 1 in electrically conductive version |

| Connection options | pipe or flange connection |

Advantages:

- corrosion resistant

- high-pressure version up 6500 Pa

- no metal parts in the airflow

- motor mounted outside the airflow

- use of different motors (explosion-proof motors) possible

The following accessories are recommended for this product:

High-pressure fan

RV 28

- can be used in all applications with medium and high air volumes

- ideal for extraction with high pressure differences

- also suitable, with optional accessories, for more demanding industrial applications, such as tank vapour extraction in the electroplating industry

- optionally suitable for installation in and extraction from ATEX zones 2 and 1

- volume flow from 500 to 50000 m³/h

- at a maximum pressure difference of > 6000 Pa

- available in 13 nominal diameters from 200 to 800 mm intake diameter

| Volume flow | 500 to 50.000 m³/h |

|---|---|

| Pressure difference | 6.000 Pa |

| Efficiency level | up to 71% |

| Nominal diameters | 13 nominal diameters from 200 to 800 mm |

| Operating temperature | 0 – 60 °C |

| Housing material | PP, PPs, PVC, PE, PVDF |

| Impeller material | PP, PPs, PVC, PVDF, FRP, CFRP, steel coated |

| Drive system | direct or belt drive |

| Atex | optionally suitable for installation in and extraction from ATEX zone 2 or ATEX zone 1 in electrically conductive version |

| Connection options | pipe or flange connection |

Advantages:

- corrosion resistant

- high-pressure version up 6000 Pa

- no metal parts in the airflow

- motor mounted outside the airflow

- use of different motors (explosion-proof motors) possible

The following accessories are recommended for this product:

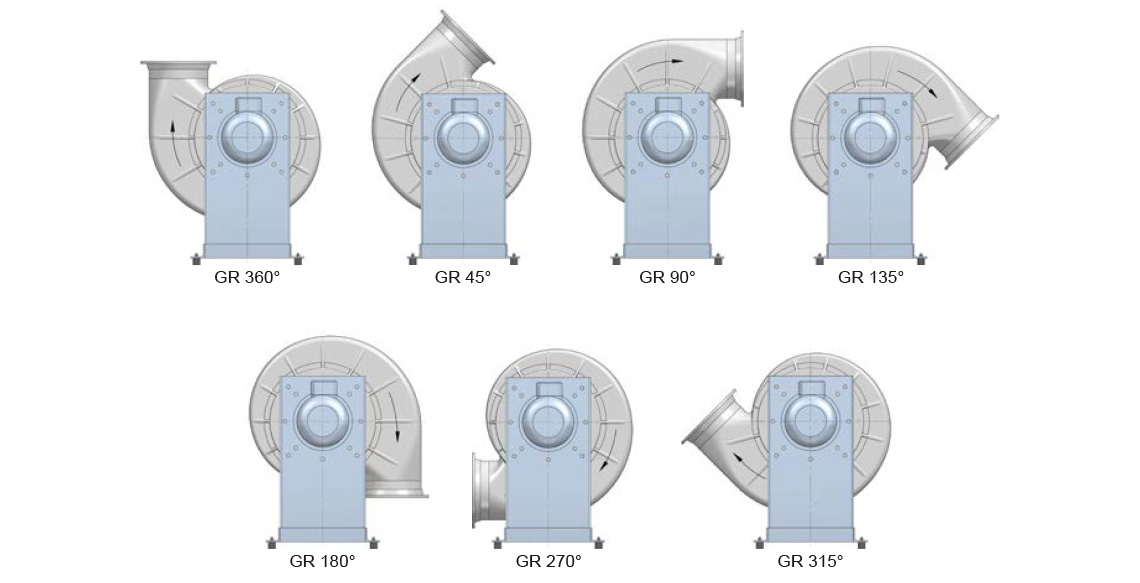

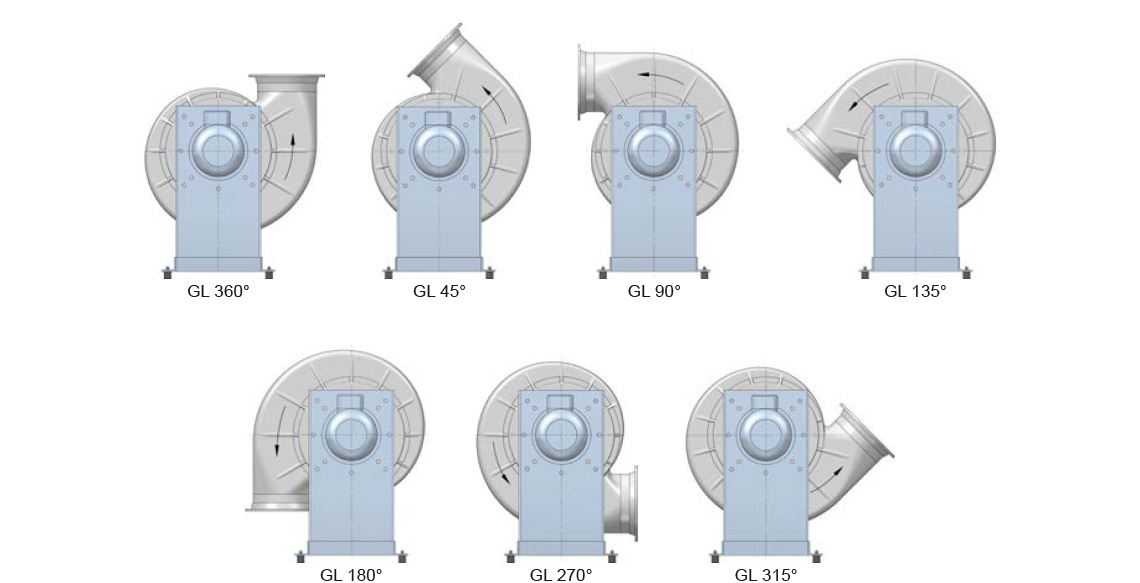

Overview of the possible housing positions:

ATEX

ATEX

Sound enclosures made of steel

Sound enclosures made of steel

Motor cover

Motor cover

Repair switch

Repair switch

Sleeve with VA tightening straps

Sleeve with VA tightening straps

C&I technology

C&I technology

Felt ring seal

Felt ring seal