We are happy to help you!

Adrian Costiniuc

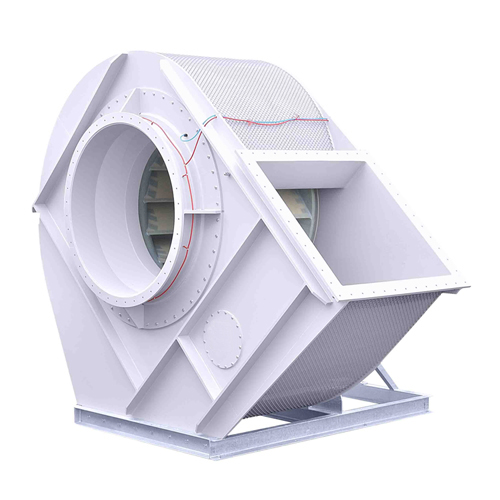

Plastic fans and components

Germany-East and Export

Sarah Di Cicco

Plastic fans and components

Germany-North, West and Export

Christoph Reimers

Plastic fans and components

Germany-South, Austria and Switzerland

Plastic fans and components

expertise and experience since 1929

HLU is a German manufacturer and specialist in fans and ventilation components made of corrosion-resistant plastics suitable for chemically contaminated exhaust air and in potentially explosive areas.

We translate our customers’ needs into innovative solutions. For example, 3D dimension sheets and QR codes on the fan nameplates are a matter of course for us, meaning you can call up the individual data card, spare parts list, declaration of conformity and operating instructions at any time. We manufacture in our own factories in Mücke Atzenhain and Ransbach-Baumbach, and our quality controls are carried out in accordance with DIN ISO 9001 and the TÜV standard.

HLU fans are used in the following areas:

- Chemical industry

- Food industry

- Electroplating industry

- Laboratory buildings

- Universities

In addition to fans, our exhaustive parts range contains components for all manner of requirements, such as predictive maintenance. It includes C&I systems, measurement and control, sound insulation and airtight shut-off.

Further accessories such as inspection covers, pipes, duct and shaped parts, and roof attachments complete our portfolio.

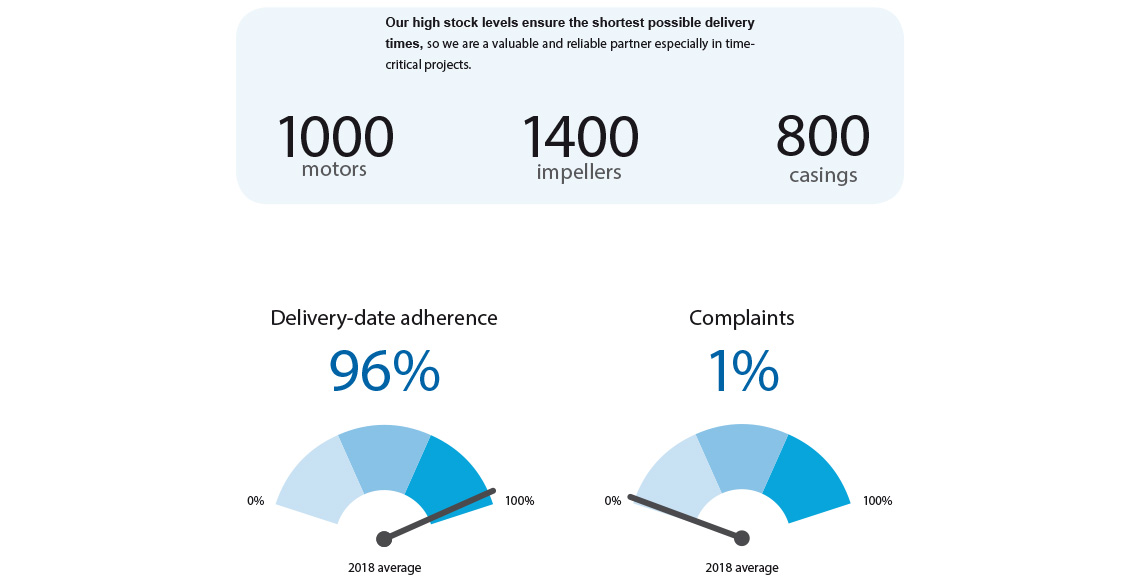

We ensure short delivery times through intelligent warehouse and logistics management.

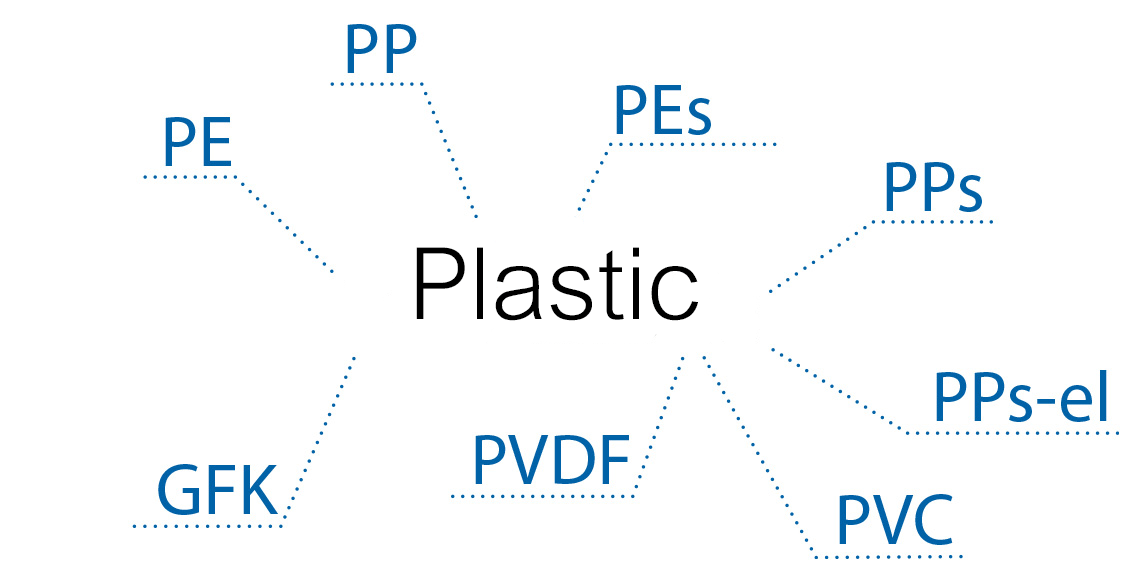

The right plastic for your application

Thermoplastic – Fibre-reinforced plastic – Plastic-coated steel

Thermoplastic

The plastics used by HLU have a high chemical resistance to many substances. Standard materials can be used for numerous kinds of applications; some applications require closer investigation. We would be happy to investigate the suitability of the materials used for your application. If you would like us to do so, please indicate the type of application and the nature of the medium.

UV and weathering resistance

Download the confirmation of the UV and weather resistance of the plastics used by HLU.

Chemische Widerstandsfähigkeit | SIMCHEM

When selecting a suitable material for a specific area of application, chemical resistance is often one of the most important criteria. SIMCHEM ONLINE is a reliable and comprehensive guide when it comes to determining the chemical resistance of SIMONA materials. The database lists more than 4,500 substances and proprietary products. It provides important guidelines for your forthcoming projects by furnishing an evaluation of the suitability of the material for a specific application or general information on the processability. SIMONA reserves the right to make changes on the basis of new information or analyses. All liability claims shall be excluded.

Project references

FRP fans

Air volume: 12 x 80.000 m³/h | 4 x 70.000 m³/h | 4 x 45.000 m³/h

Scope of supply: 12 x HF R 1250-13 D | 4 x HF R 1120-13 D | 4 x HF R 900-13 D

Laboratory exhaust air

Scope of supply: 25 centrifugal fans with frequency converter for outside installation

Air volume: between 1.000 m³/h and 20.000 m³/h

Powerful HF R 800-13 D

Scope of supply: 3 x HF R 800-13 D with FRP-CFRP hybrid impeller

Air volume: 3 x 50.000 m³/h