Specialist in corrosion-resistant plastics

since 1928

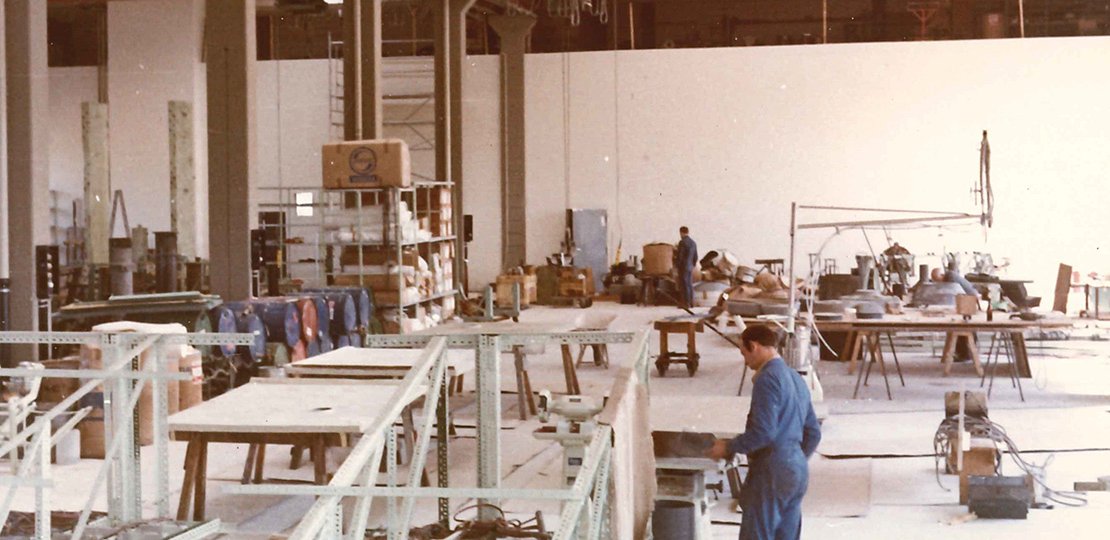

HLU – Hürner Luft- und Umwelttechnik is a progressive German company that marries future-oriented air technology with sustainable environmental technology. With more than 180 experienced and highly trained employees, we support you in all supply and exhaust air engineering tasks with bespoke solutions. We manufacture almost all our fans, components and parts in our own factory in Mücke-Atzenhain. Our plastic equipment and systems are produced in Ransbach-Baumbach.

Our ATEX-compliant plastic fans, components and equipment are used all over the world where maximum chemical resistance, reliability and durability are required. With high project competence, we plan, manufacture and install customised solutions for you and support you with reliable maintenance and excellent service.

Team

We are proud of our professional and highly committed team of qualified and experienced employees. Thanks to them, we can assure our high performance in planning, manufacturing and installing complete ventilation systems – from supply air to exhaust air. We provide further training and staff development for our employees in our in-house HLU Coaching Academy. Our engineers, plastic welders, technicians and project managers regularly take advanced training courses to deepen and update their knowledge This is how we ensure our continued innovativeness and further develop the progressive services with which we support you.

Our values

We have firmly anchored our values in our corporate and management culture. We base our thinking and activity on these values:

Progressive.

We have been actively shaping the market since 1928. Our goal is to recognise future trends and needs early on and to deliver solutions to tomorrow’s challenges today. To achieve this, we have an average annual development budget of 340,000 euros and invest around 600,000 euros each year in state-of-the-art technology and in expanding our production facilities.

Reliable.

Fully respecting commitments, deadlines and quality parameters is our top priority. Each of our 182 employees feels personally responsible for this. This important aspect of our culture is clearly reflected in our process and quality management, which enables us to systematically maintain and optimise our reliability and dependability. We set responsibilities, deadlines and prices reliably, bindingly and unambiguously before a project starts. This allows us to create transparency for you, reduce the number of contact people and the unnecessary costs, and optimise the project length.

Measurable.

Our performance is measurable. From stock levels to delivery-date adherence and complaint rates, we place great importance on 100% transparency – at product level, too: with innovative sensors for predictive maintenance, we ensure continuous condition monitoring and complete transparency regarding the process reliability and performance of our systems and fans. Through this, we create safety, transparency and trust.

With four divisions, HLU offers perfect solutions to all tasks.

Present worldwide and on site when you need us

In addition to the facilities in Mücke-Atzenhain, Schwalbach am Taunus and Ransbach-Baumbach, HLU has subsidiaries in China, Singapore and Malaysia, as well as partners in Europe and overseas. This means we are available for you around the world and can support you in all your ventilation needs wherever you are.

HLU value chain

One of HLU’s major strengths is its seamless value chain. From research, parts and component production, and technical planning to assembly and maintenance, we perform all our services in house. This makes HLU unique in terms of quality, compatibility and delivery speed of products, solutions and services.

About HLU

Hürner’s history

Certificates

Memberships of specialised associations

VDMA e. V.

With around 3,200 members, the Mechanical Engineering Industry Association is the largest network organisation and thus the most important mouthpiece of this industry in Germany and Europe. Mechanical and plant engineering is one of the largest economic sectors and most research-intensive industries in Germany, making it a driver for innovation.

ZVO Zentralverband Oberflächentechnik e. V.

Modern electroplating and surface technology is developing into a key industry. For industry, the authorities and the political sphere, the ZVO (Germany's central association for surface technology) is an important contact for questions concerning economy, environment, energy and education with a focus on electroplating and surface technology. The ZVO is a technical and scientific association that furthers the interests of industry and trade, in-house coaters, raw-material and process suppliers, plant manufacturers, component manufacturers and service providers in the German electroplating and surface technology.