We are happy to help you!

Frank Kluge

Plastic equipment and system construction

Nikolaus Wessler

Plastic equipment and system construction

Plastic equipment and system construction

Our product range includes exhaust air scrubbers, laboratory gas scrubbers, tanks, evaporators, spin separators and inertia droplet separators.

The products are manufactured in our factory in Ransbach-Baumbach. Our quality controls are carried out in accordance with DIN ISO 9001 and the TÜV standard.

Our solutions are mainly used in wet chemical processes and have proven their worth in the following areas:

- Chemical / Pharmaceutical

- Semiconductor, Solar and Surface technology

- Waste and Wastewater technology

- Composting

- Textile and Food industry

Suitability and chemical resistance of thermoplastics in equipment and system construction

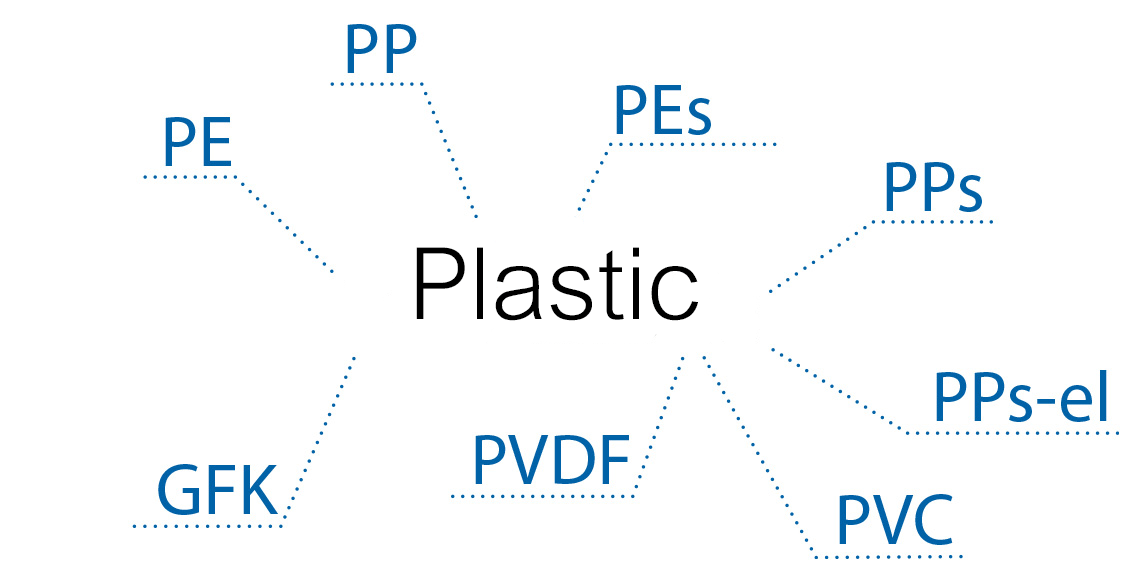

When selecting the appropriate material for a specific application, its chemical resistance must be considered. This depends on the medium, concentration, temperature, manufacturing conditions and load. In many cases, fire behaviour, weather resistance, physiological safety, electrical conductivity, etc. are important properties that are also considered when selecting materials for our products. In most cases, the standard materials listed below are used.

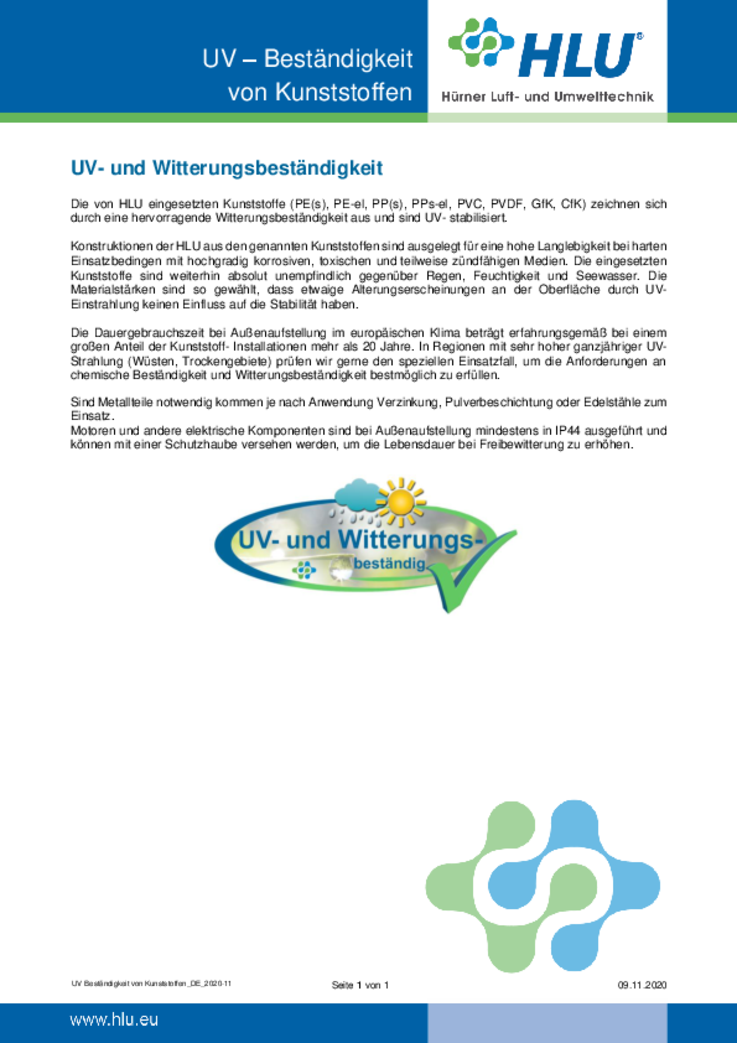

UV and weathering resistance

Download the confirmation of the UV and weather resistance of the plastics used by HLU.

Chemische Widerstandsfähigkeit | SIMCHEM

When selecting a suitable material for a specific area of application, chemical resistance is often one of the most important criteria. SIMCHEM ONLINE is a reliable and comprehensive guide when it comes to determining the chemical resistance of SIMONA materials. The database lists more than 4,500 substances and proprietary products. It provides important guidelines for your forthcoming projects by furnishing an evaluation of the suitability of the material for a specific application or general information on the processability. SIMONA reserves the right to make changes on the basis of new information or analyses. All liability claims shall be excluded.

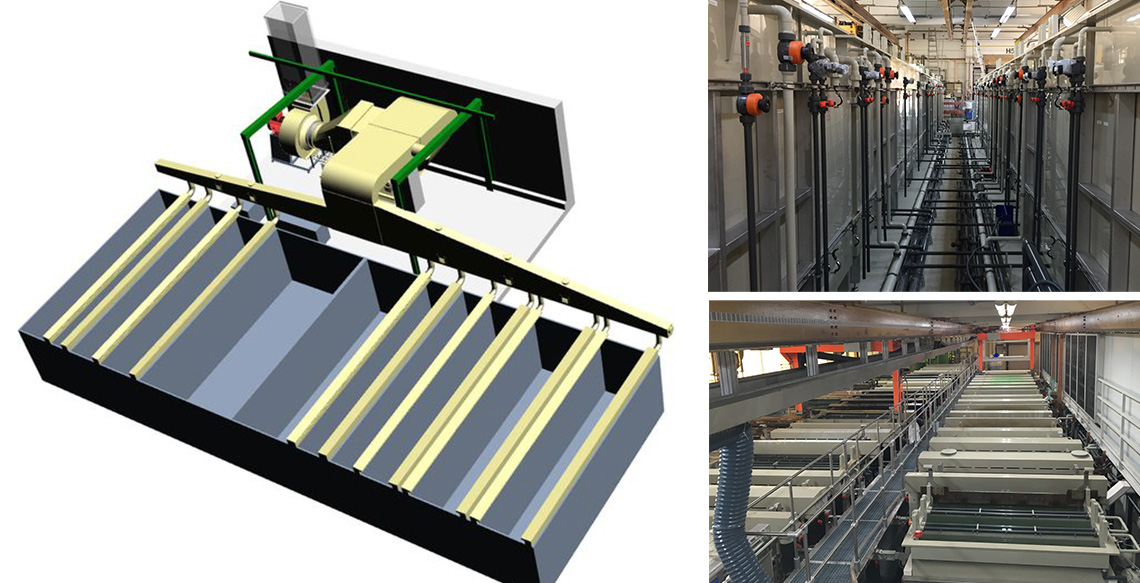

We realise your ideas and specifications. Equipment and complete systems made of plastic

from planning through to commissioning

Whether it’s complete exhaust-air-purification and electroplating plants, storage and pumping stations, process tanks, filter systems or many other applications, there are almost no limits to the possible applications of today’s plastics processing.

When we produce and install your systems, you benefit from the expertise we have accumulated through completing countless projects over the years.

We provide you with the following services

- planning and designing your entire systems, tanks, pipelines and steel constructions

- consultation and support from the initial idea right through to commissioning our components

- on-site measurement prior to construction of the required components

- 2D and 3D construction of systems, tanks and so on with the latest CAD technology

- preparation of the associated structural calculations, technical documentation, flow charts, layout plans, piping isometrics and production drawings

- support with implementation, TÜV inspections, customs inspections and solutions economically suited to your application area

- advice on the right material to use, with an almost unlimited choice of colours. Examples of thermoplastic construction materials are PE, PP, PVC and PVDF, and composite materials such as PP/FRP, PVC/FRP and PVDF/FRP.

When designing process engineering components such as scrubbers and silencers, we work together with experienced engineering offices. Our products’ dimensions are only limited by road traffic regulations and building constraints.

Project references

Transportable flue-gas cleaning system

Air volume: 700 m³/h

Scope of supply: Production of the complete plastic components, incl. installation of the complete system with the liquid piping in the container.